In total, we process between 300-400 tonnes of aluminium each year. We produce everything from simple cabinets to complex and space-consuming installations.

MAN AND MACHINE

No machine can work without a good operator. Therefore, we invest heavily in in-house competence and knowledge. The interaction between man and machine is important for efficiency and quality.

SHEET METAL PROCESSING

We have all the necessary equipment required to be a total supplier in sheet metal processing. In our plate department, we produce e.g. products for the fiber industry, cable ducts and cabinets. Our automated drop forge and breaking machine gives us great flexibility in response to the customer’s wishes and requirements.

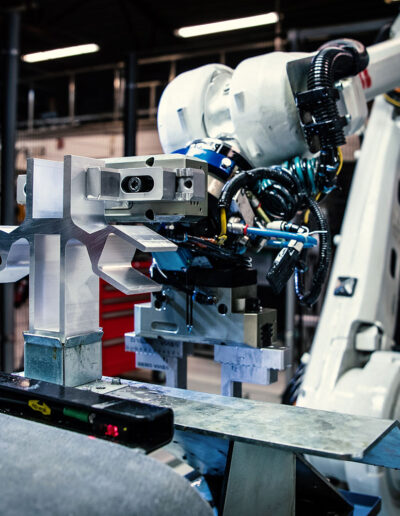

CNC MACHINING

Our fully automated CNC milling machine and other manual milling machines can work continuously with small and large product series. Advanced robotic arms pick up and supply the machine in question with blanks, even after hours.

Machines:

- Mazak VTC-200C

- Mazak VTC-530C, – Smooth Technology

- Mazak VCS 530C integrated with ABB-robot and camera

PUNCHING

As a leader in cost-effective punching processing, we rely on good machines from leading manufacturers. Sheet metal details for cabinets, enclosures, profiles and ducts are cost-effectively drop-forged out in our automated drop-forging machine.

Machines:

- Amada EM 2510NT, integrated in/out-loading with robot arm.

TURNING

Our CNC-controlled lathe is equipped with a bar feeder and UR robot that handles workpieces in and out of the machine. This ensures predictable quality and efficiency, every time.

Machines:

- Mazak Quick Turn 200 MSY, integrated with UR-robot and feeder.

WELDING

We also perform manual welding with TIG and MIG.

Machines:

- ABB welding robot with 3-axis manipulator, integrated with Fronius CMT welding machine.

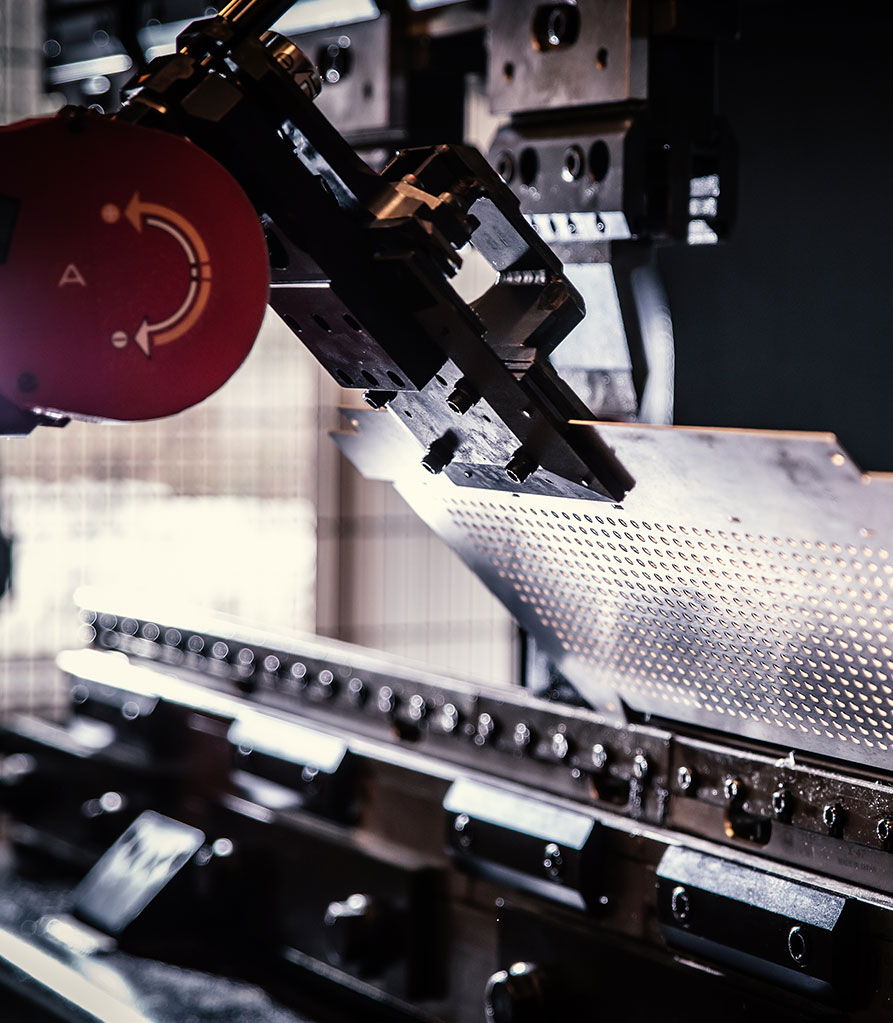

BENDING

Our fully automated bending process is built around an advanced robotic system that takes the workpiece through all the tasks required until having a finished product. This means that we can bend large product series quickly and precisely around the clock.

We can also produce finished products in our 2 manual bending machines.

Machines:

- Amada Astro 100NT HDS 1030 robotcell

- Amada HD 1003NT

- Amada HFE M2 5012

DRILL/MILLING CENTER

CNC-controlled long machine for easier milling/drilling of profiles with a length of up to 7 metres. The milling spindle can rotate 240 degrees for machining, for example, round tubes.

At Normeka, we focus on the interaction between man, machine and robot. Central to succeeding with this has been the development of competence among our employees. Our robots can pick up and deliver workpieces in milling machines, lathes, press break machines, drop-forging machines, as well as our special production in AmpliForm. This allows production to run 24/7.

Our welding robot with a rotating manipulator quickly assembles large complex constructions.

This machine gives us predictable quality and efficiency, every time.

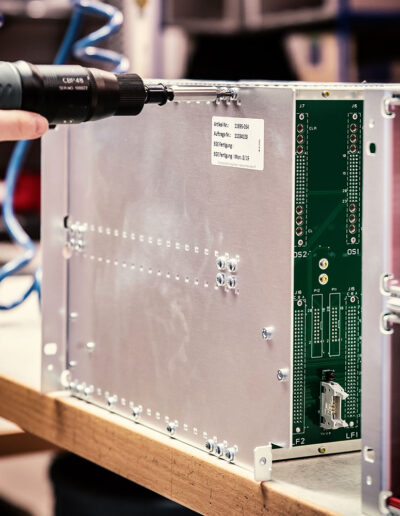

However, not everything can be solved with machines and robots. Our employees possess a very high level of expertise, something from which we benefit particularly in smaller and more complicated product series.

Our mechanical department has a high level of expertise, and with advanced machinery we can manufacture cabinets from raw material to finished product. The cabinets can be delivered with the desired surface treatment and mounting of contents.

We manufacture all types of aluminium enclosures according to measurements and wishes.